PRODUCTION

All our parts have come a long way since the digital or paper project to its final form. To meet a high expectations of our customers – drivers, prototypes are tested in various harsh conditions in real world environment. Basing on the results we can single out strong and weak points of the design, after improving it and eliminating all flaws we can be sure of its quality and reliability.

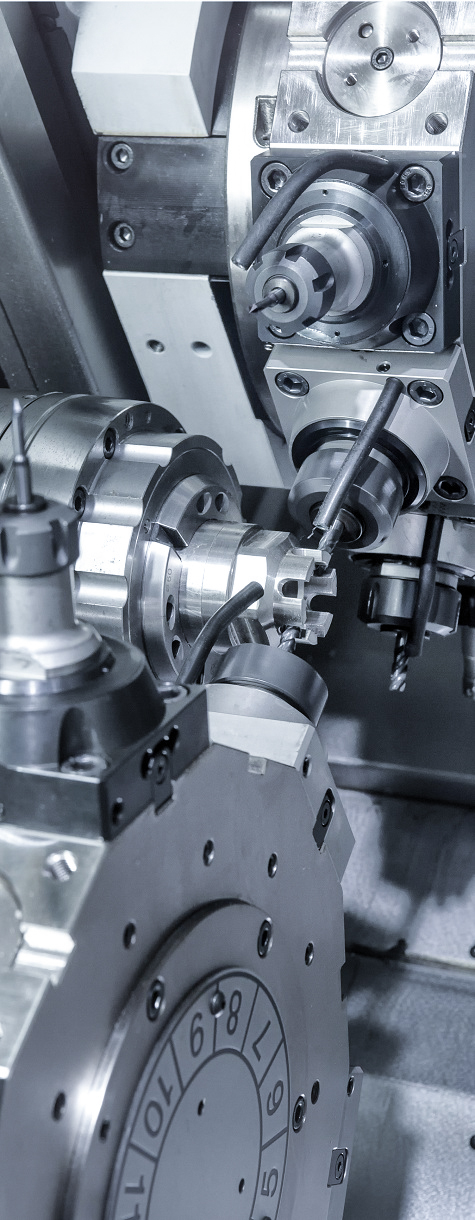

The use of advanced cnc machines and close cooperation with friendly companies allows us to produce a wide range of car parts and many other industrial components. Apart from our product line we realize orders to any kind of automotive brand or other equipment. During the production process we use various manufacturing methods such as :

- CNC turning

- CNC milling

- CNC grinding

- conventional machining

- metal stamping and drawing

- laser cutting

- heat treating

In cooperation with other companies we produce :

- castings – aluminium, cast iron and plastic

- various gears and worm shafts

Some of our realisations :

- hydraulic components – master and slave cylinders, hydraulic “spill free” connectors

- complete wheel hubs

- steering components, track rod ends, track rods

- suspension components – sport shock absorber parts

- various metal components for cars and other equipment

We can work for You and Your business. Please do not hesitate to contact us.